What Causes Propeller Vibration and How Do I Fix It?

Propeller shafts are strong and long-lasting, yet prone to vibration. Excessive torsional vibration can be identified using modern vibration analysis techniques such as ultrasonic testing or magnetic particle testing. Propeller shaft bearings may become damaged from insufficient lubrication or overload. Hence, it starts to vibrate. Regular inspection and lubrication can help avoid this situation. But excessive vibration can be very concerning, as it can be due to several other problems:

Mass Imbalance

Even minor variations in propeller blade mass distribution can create significant vibration. Excessive vibration levels can cause structural fatigue in engine components, leading to their premature failure. Dynamic propeller balancing is the best way to prevent out-of-balance conditions from reaching harmful levels.

The solution: Magnets. They are used during this process to shift imbalance weights across the rotor to achieve balance, saving both time and money by maintaining propeller balance. Here’s the complete guide on choosing the right propeller pitch.

Damage (Dents, Nicks, Corrosion, Bending)

Damage to a propeller blade can cause vibration to increase and become hazardous. Propeller damage may result from hard cornering or hitting an object during the boat trip. Additionally, a loose prop can also cause significant vibration issues.

A loose propeller may wobble during operation, leading to uneven forces that transmit through the prop shaft and into the boat, often felt in the engine compartment. It is essential for boat owners to regularly inspect and ensure the prop is securely installed to prevent such vibrations.

Damaged blades may lead to cavitation, disrupting the flow of water around the propeller and decreasing efficiency. As a result, more energy must be expended in maintaining speed, increasing fuel consumption.

Misalignment

Misalignment is a common issue within marine power systems that often leads to vibration. It takes two forms: parallel and angular:

- Parallel misalignment occurs when prop shaft center lines are close together.

- Angular misalignment happens when two shaft centerlines intersect at an oblique angle.

Misalignments of both kinds can cause mechanical issues, from excessive vibration and component wear to failures such as bent shafts and fractured couplings. All these problems reduce efficiency and raise propeller maintenance costs.

If left unchecked, misalignment could even lead to catastrophic results such as shaft bending or fractured couplings that reduce efficiency and increase maintenance costs.

Obstructions like Fishing Line

An obstruction prevents something from passing, like a roadblock that blocks cars from entering a street. A block can also refer to parts of your engine or running gear that restrict movement or prevent proper functionality.

For example:

- Crankshaft imbalance

- Excessive compression

- Wear on vibration isolators

- Cracked engine mounts

How to Fix Boat Propeller Vibration?

Propeller cavitation creates vibrations by rapidly turning water pressure into vapor, producing popping bubbles that implode around propeller blade tips. Plus, this process may damage shaft components as well as components attached to them. That’s why early detection and repair is the best solution you have.

Inspect the Engine Mount

Make the first step of your investigation an inspection of the engine itself. Make sure the seacock and strainer are open and clear of debris; check that coolant levels meet manufacturer specifications; look out for signs of leaks, etc.

Take out your propeller and start the engine to determine whether it is at fault and which repairs or replacements are necessary. Also, you can test a different prop. Doing this may also allow you to gain insight into any necessary boat propeller replacement requirements.

Bent propeller blades can also cause vibration at higher speeds, so be sure to check for misalignments or damages such as dents or gouges on any blades in order to assess if any need to be straightened out by professionals. Bent blades may wreak havoc on the balance of your propeller, resulting in vibration at higher speeds – so inspect it closely!

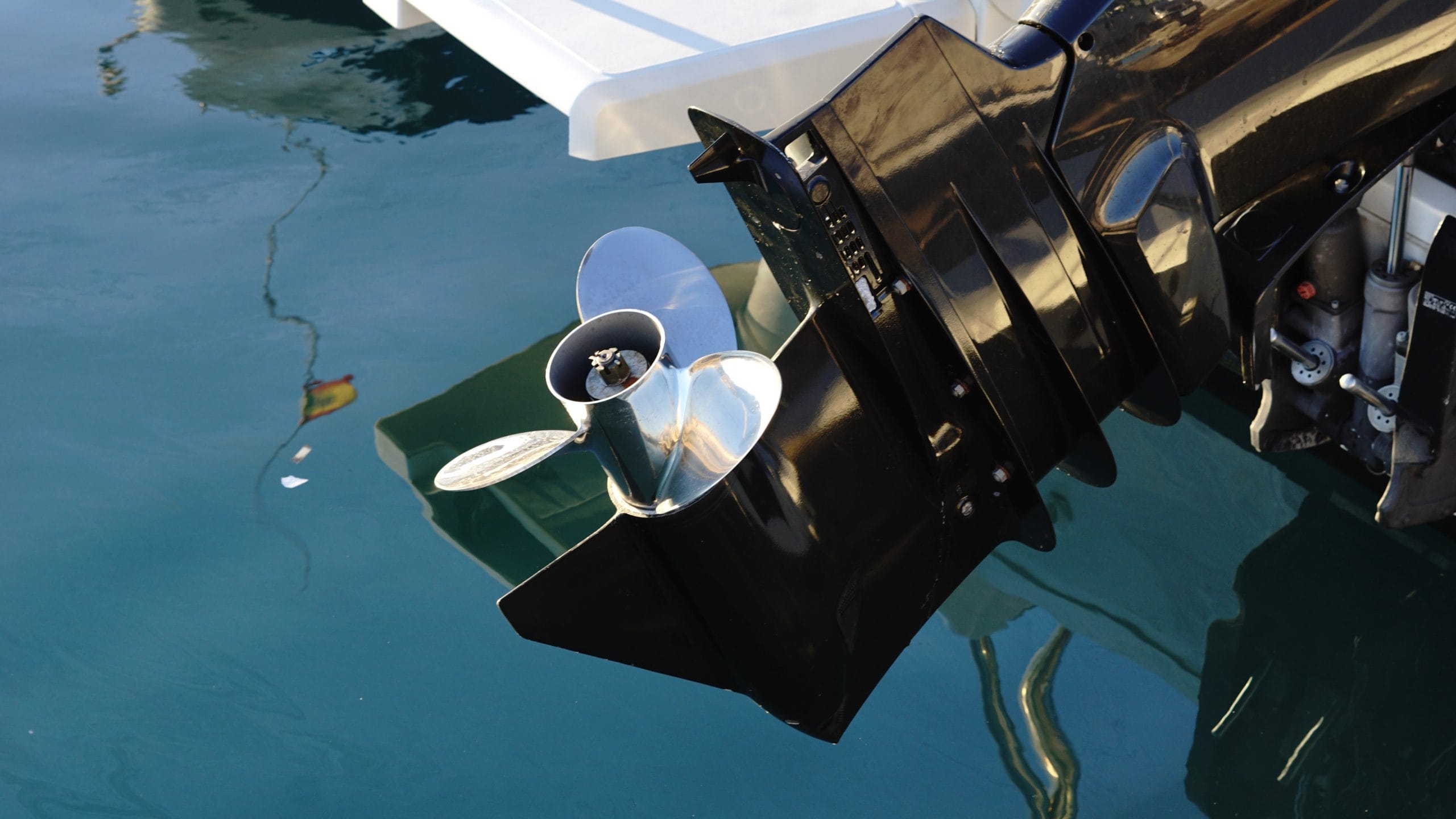

Inspect the Propeller

If vibration is felt through your hull and steering system, the first step should be inspecting your propeller. Damage caused by nicks or dings to its blades could throw off its balance and reduce efficiency.

Bent propeller shafts can cause vibration at higher RPMs. Depending on the severity of the bend, repair may be possible, but in many cases it’s necessary to replace it entirely so as to prevent further damage to other components.

Regularly cleaning your propeller will remove marine growth and barnacles while using protective coatings designed to reduce corrosion and keep blades cleaner for longer.

Inspect the Propeller Shaft

When investigating any unexpected vibration, the propeller should always be the first place you look. Unwanted vibration due to damaged propellers usually occurs at higher RPMs and can be confirmed by removing it and running your engine to see if vibrations still persist.

If it is difficult for you to rotate the shaft by hand, this could indicate an alignment issue between the propeller and transmission couplings. If that is indeed the case, separate the shaft from the transmission and use a protractor to measure alignment.

Inspect The Bearing

As part of your propeller inspection, take special note of the cutless bearing. This brass-lined, grooved piece of equipment allows water to enter it to keep it lubricated as its shaft rotates within it. If the cutlass bearing exhibits severe cracking or excessive wear, you must replace it immediately to avoid mechanical vibrations that could potentially harm other parts of its drive train.

Final Thoughts

Propeller vibration isn’t something you can just ignore; it’s your boat’s way of telling you something’s off. Regular inspection, cleaning, and timely maintenance go a long way in keeping your prop running smoothly. Remember, a well-balanced and properly aligned propeller enhances your boat’s performance, fuel efficiency, and overall ride quality. Treat your prop right, and it’ll reward you every time you push the throttle.

Upgrade to a Smoother, More Efficient Ride with Prop Depot

If your propeller’s been giving you trouble, don’t let it hold your boat back any longer. At Prop Depot, we offer a wide range of high-performance boat propellers engineered to restore balance, reduce vibration, and boost your boat’s overall efficiency.

Every prop we sell is tested for balance and performance, ensuring a smoother, quieter, and more responsive experience on the water. So, if your current prop has seen better days, don’t wait for the vibration to get worse; contact us now!