A cutlass bearing sits quietly under your boat, yet it plays an essential role in how smoothly everything works. It supports the propeller shaft as it rotates through the stern tube and the hull. Most cutlass bearings use a rubber lining bonded to a metal shell. Water flows through minor grooves in the rubber to keep the bearing cool and lubricated while the prop shaft spins. Maintenance for this small part is often overlooked during routine boat maintenance. That mistake can cost time and money. We will cover the key warning signs and exactly what to watch for. If you want to learn how the bearing works, how long it lasts, how much movement counts as too much, and when replacement becomes urgent, keep reading.

Understanding the Role of a Cutlass Bearing

A cutlass bearing, also called a cutless bearing, supports the shaft between the engine and the propeller. The bearing sits inside the stern tube or strut, often near the p bracket. Its outer diameter presses tightly into the strut, while the inner rubber surface holds the shaft steady.

As the engine sends power through the coupler and flange, the shaft rotates. The bearing controls side-to-side movement and keeps the shaft aligned with the engine mounts. Without a healthy bearing, vibration increases, wear accelerates, and other parts start to suffer. This bearing stays water-lubricated. It relies on flow through the grooves to stay cool. When rubber wears down or grooves disappear, friction rises fast.

How Long Does a Cutlass Bearing Usually Last

Most bearings last several years. Many owners replace an old bearing every five to seven years. Some last longer. Others fail sooner due to heavy power, poor alignment, or dirty water.

A boat that sails often may wear the bearing faster than a boat that sits idle. Strong reverse thrust, tight maneuvers, and aggressive propeller loads also speed up wear. A bearing installed years ago may look fine from a distance, but still cause trouble.

Excessive Shaft Movement Signals Trouble

Movement tells the story better than any calendar. With the boat hauled or lifted in the yard, grab the shaft near the cutlass. Push it up, down, and to the opposite side. Watch closely and feel the wiggle.

A healthy bearing allows very little play. If you see clear movement or hear a click, the bearing has reached the end of its life. Many mechanics follow a simple rule: if movement exceeds about 1 millimeter per inch of shaft diameter, replacement becomes necessary. Do not ignore how much movement you feel. Excess play lets the shaft bend slightly while it rotates, which can also compromise shaft seals. That stress spreads fast.

Vibration Under Power Warns You Early

Excessive propeller vibration ranks among the clearest warning signs. You may feel it through the hull, rudder, or even the helm. It often appears at low speeds or while shifting from forward to reverse.

An old bearing no longer holds the shaft centered. The shaft then spins off-balance. That imbalance travels through the coupler, engine mounts, and hull structure. If vibration appears suddenly, inspect the bearing right away. Waiting risks damage to the prop, strut, or engine alignment, and you don’t want that.

Noise Changes You Should Never Ignore

A worn cutlass often speaks before it fails. Listen for squealing, rumbling, or knocking sounds. These noises often rise as the shaft rotates faster.

Rubber grooves wear down over time. Once the rubber smooths out, the water flow drops. The bearing runs hotter and louder. Heat accelerates wear and can even cause the rubber to split from the shell. Noise during idle or low power often points straight to the bearing. Importantly, some maintenance may be required on the propellers, which means you might need to remove them to inspect or service both the prop and the bearing properly.

Visible Rubber Wear & Grooves

Inspection during a haul-out gives valuable clues. Look closely at the rubber lining. Deep grooves should run the length of the bearing. These grooves allow water to flow and keep friction low.

If the grooves look shallow or uneven, the bearing is near failure. Cracks, splits, or missing rubber sections demand immediate replacement. Also, inspect the outer diameter fit. Any sign that the bearing spun inside the strut means trouble. A bearing must stay tight. Set screws help lock it in place. Loose screws allow movement and wear on the strut.

Propeller & Shaft Alignment Issues

A worn bearing often hides behind alignment problems. If you struggle to align the engine to the shaft flange, suspect the bearing. Excess play changes the shaft centerline.

Misalignment puts strain on new engine mounts and the coupler. You may replace mounts and still feel vibration. The real culprit often sits aft, not forward. Always inspect the cutlass bearing before installing new engine mounts. Skipping this step wastes effort and money.

Damage Risk If You Delay Replacement

Ignoring a worn bearing invites a chain reaction. The shaft can score or develop grooves. The strut bore may wear out of round. The propeller may suffer uneven blade loading.

In severe cases, the shaft can contact the stern tube. That contact risks hull damage and water intrusion. Replacement at the right time helps prevent damage that costs far more than a new bearing. Most importantly, one small part protects many larger systems.

Signs During Reverse & Maneuvering

Pay attention when shifting into reverse. A bad bearing often causes clunking or sudden changes in vibration. Reverse loads the shaft in the opposite direction. That shift exposes play you may not notice in forward motion.

Docking maneuvers reveal problems fast. If the boat shakes or rattles while backing, inspect the bearing soon.

Measuring Wear the Right Way

Never rely on feeling alone. Use a stick or dial indicator if possible. Measure movement at the bearing while pulling the shaft in opposite directions. Record the distance.

Compare movement to shaft length and diameter. Imperial measurements remain common in many yards, including those in Australia and beyond. Precision matters here. If numbers exceed tolerance, replace the bearing. Do not wait for failure.

When DIY Replacement Makes Sense

Some owners handle replacement with strong DIY skills. The job often requires hauling the boat, removing the prop, loosening set screws, and pulling the old bearing. A proper puller makes the job easier. Some use a split bearing or press-style tool.

A hammer may help in tight spaces, but careful control matters. Damage to the strut creates bigger problems. Always inspect screws, grooves, and fit before installing a new cutlass bearing. If access proves tight or alignment feels unclear, call a mechanic. Experience saves time.

Installing a New Cutlass Bearing Correctly

A new bearing must fit tightly in the strut. Here are the basic steps you can follow for the installation process:

- Clean the bore fully before installation

- Align grooves to allow proper water flow

- Tighten set screws securely

- Recheck the shaft alignment at the flange and coupler

- Confirm smooth rotation by hand

- Watch for binding or resistance

You can test the bearing under power once launched. A smoothly operating bearing will confirm a successful installation.

Cutlass Bearing Warning Signs You Should Catch Sooner

A cutlass bearing rarely fails without warning. Movement, vibration, noise, and wear all send clear signals. The key lies in watching and inspecting before damage spreads. Regular checks during haul-outs and dives help you spot issues early. Replacement at the right time keeps your boat smooth, quiet, and reliable. In the end, a small bearing carries big responsibility. Treat it with attention, and it will return the favor mile after mile under power or sail.

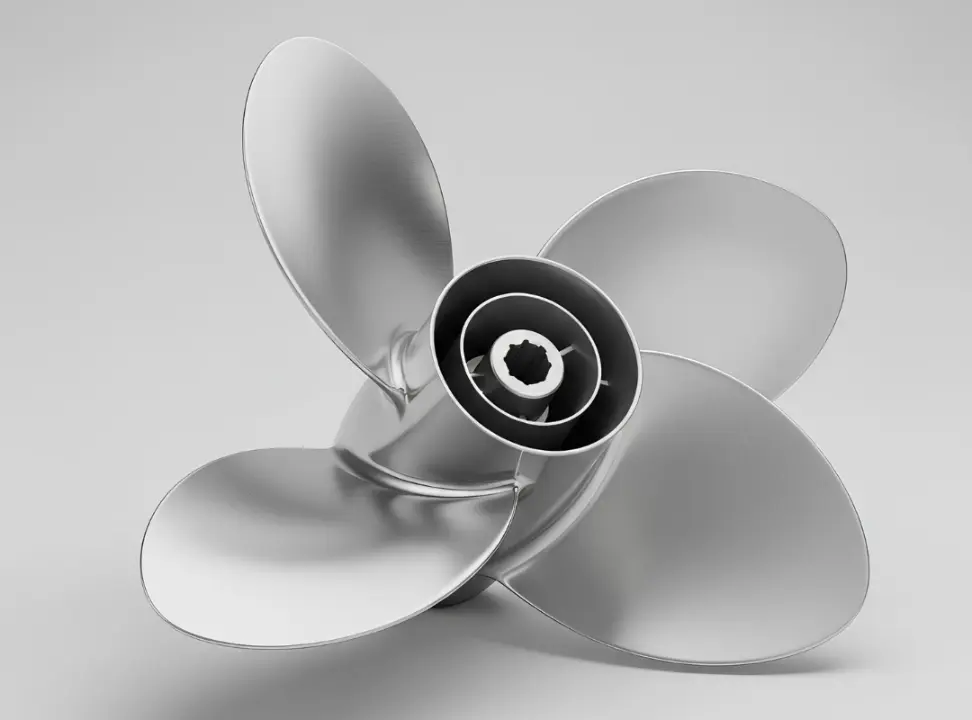

Prop Depot Repair Services for Cutlass Bearing Wear

If cutlass bearing wear has you worried about vibration or shaft movement, you’re already thinking ahead. Prop Depot supports boat owners with balanced Mercury propellers and precise propeller repair services that reduce drivetrain stress and protect critical components. Addressing these issues early prevents larger mechanical damage. Contact us now or shop our Mercury props on the website.